A Laser Micro-Gauge is an instrument suitable for outside diameter or width measurement with contact-less operation.It is composed of a sensor part and a Display.

|

|

|

Sensor part |

Display |

■Features

・Ultra high speed measurement

The laser beam scanning speed of 707m/sec(LMG607) and scanning frequency of 3600 scans/sec allow it to measure with high speed and high accuracy an object which moves or vibrates.

・Non-contact measurement

It does not affect an object to be measured. Even a soft or hot object can be measured without difficulty.

・Many functions

Diameter and Gap measurement. Maximum value, Minimum value, Max-Min value and Mean value, etc.

Diameter of drills or endmills which has odd bits can be measured.

・Easy to use

Use of visible laser. Easy calibration.

・Many Devices

10 kinds of devices cover a measuring range from 0.01mm to more than 1m.

Special models : High temperature object model, Radiation-resisting model and etc.

・Computer interface

RS-232C, Options:GP-IB, Centoronics and BCD

・Analog output for analog recorder

・High reliability

・IP64, CE marking

・LMG series is calibrated by using authorized gauges.

■Applications

Laser Micro-Gauge measures diameter, width, thickness, gap spacing in various industries

・Measuring dimensions on-line of wire, bar, rod, pipe material, processed machine goods, molded or forged goods, etc.

・Measuring dimensions of frgile, and transparent materials such as rubber, glass and plastic goods.(The measuring function of transparent material is optional.)

・Measuring dimensions of expanding, contracting and transforming materials.

・Measurements of outer diameter, roundness, and runout of pipes, rollers, bars and rods made of any materials.

・Measuring dimensions of high speed running wire and belt-shaped material.

・Measuring shape of connectors and IC pins.(Optional)

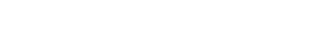

■Measuring principle

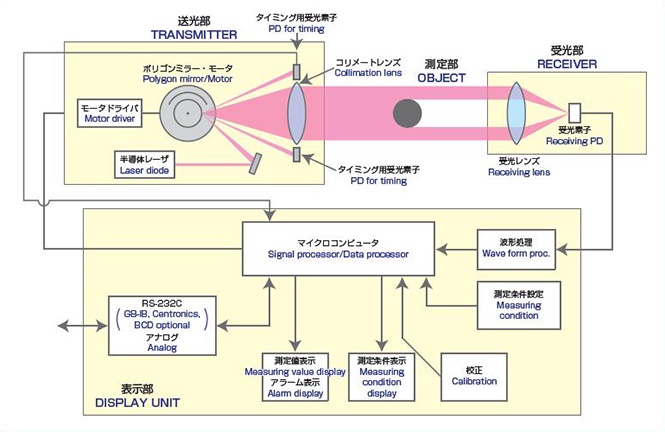

■Measuring functions

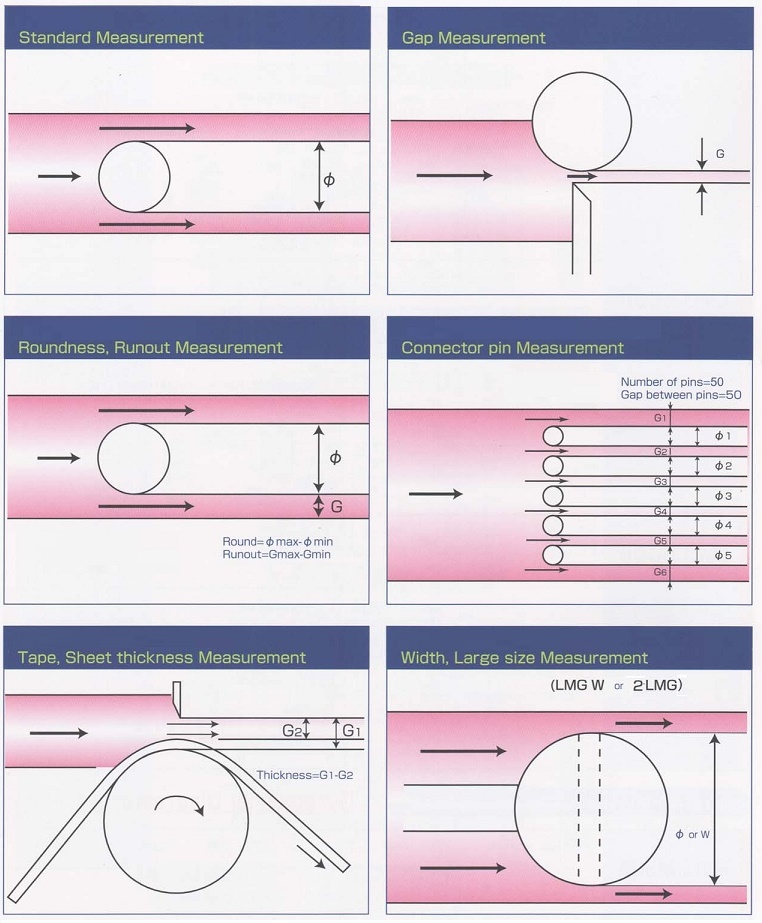

■Measurement samples