|

|

On-line type metal thickness measurement system, using EMAT/FOD.

+/-0.1mm accuracy, upto 200 deg Celcius.

This product is approved by JSME S TB-1 2009, as pipe thickness management standard technology.

Please refer to technical information.

You can download catalogue below.

>>EMAT/FOD system (application/pdf:675.6 KB)

■Technical Information

|

EMAT/FOD metal thickness measurement |

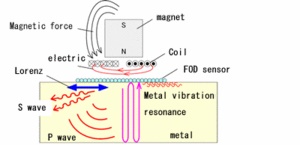

By combining FOD and magnetic, metal thickness is measured. According to Flemming law, EMAT generates vibration into metal, where FOD sensor detects such vibration frequency. The strongest frequency is corresponding to metal thickness.

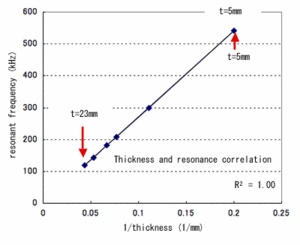

Metal thickness as d, velocity as c, frequency as f, when the following formula is fulfilled, resonance occurs. Meanwhile, FOD sensor can detect in-plane vibration of metal, thus FOD can detect above resonant frequency and amplitude easily.

d = c / 2*f

EMAT (Electromagnetic Acoustic Transducer) is used as heat-proof ultrasonic exciter by Lorenz force and/or magnetic forcee. By using this force, ultrasonic wave is generated into metal, and voltage frequency is swept. At a certain thickness, ultrasonic comes into resonance and obtains the maximum amplitude, which is thickness-correlated.

Technical features :Conventional thickness measurement is 1) Time-based inspection 2) Shutdown inspection at accessible temperature by measuring one point to another 3) employment of much human power and time. By EMAT/FOD system, 1) Continual monitoring of thickness at important fixed points, 2) Permanent sensor probes inside the insulation 3) On-line monitoring even under high temperature operation 4) Cost savings from scaffolding, insulation disassemble and reassemble work.

Applicable area :

– Piping (elbow also) and pressure vessels

|

|